Showing 1–12 of 42 results

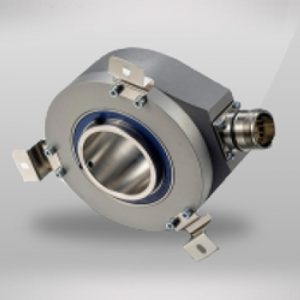

HALLOW SHAFT

Hohner manufactures a range of hallow shaft encoders from 4 to 42 mm in diameter, as well as many accessories for correct adjustment through an encoder on industrial devices. Hohner shaft halo encoder has CE and ROHS standards and also has an IP65 protection rating. It should be noted that the programmable encoder of the PR90H series is considered to be a series of Hewlett-Packard encoders. You can contact our experts to find out how to test the encoder, how to install the encoder and get the technical data of various encoder, as well as the catalogue of the encoder types.

Hollow Shaft Rotary Encoder is a type of rotary encoder in which the shaft in the middle of the encoder is hollow. This design allows users to directly pass the motor shaft or other components through the middle of the encoder, without the need for a direct physical connection to the encoder shaft.

Main Features of Hollow Shaft Rotary Encoder:

Hollow Shaft Design: Unlike conventional shaft encoders that require the encoder shaft to be connected to the motor shaft, the hollow shaft encoder can be easily mounted on the motor shaft or other component and does not require a complex mechanical connection. In this design, the motor shaft passes through the middle of the encoder.

Easy Installation: This feature greatly simplifies the installation process, as there is no need to connect the encoder to the shaft using an additional shaft or screw. These types of encoders also usually have the ability to be installed quickly and without the need for complex tools.

Accurate rotation and position measurement:

Like other rotary encoders, hollow shaft encoders are able to measure shaft rotation with very high accuracy and send position, speed and direction of movement to control systems.

Greater flexibility in various applications:

The hollow shaft design is very suitable for applications that do not require a direct connection of the shaft to the encoder. This feature makes these types of encoders used in various industries, especially in places with space constraints or a need for high flexibility.

Suitable for motor and gearbox systems: Hollow shaft encoders are usually used in systems that require a precise combination of motor and gearbox.

Types of Hollow Shaft Rotary Encoders:

Incremental encoders: These encoders are used to count pulses and determine changes in shaft position.

Absolute encoders: These types of encoders are able to determine the exact position of the shaft at any time, without the need to count pulses.

Advantages of using hollow shaft rotary encoders:

Simple and fast installation: Due to the hollow design, installation is much easier than conventional shaft types.

Reduced space requirements: The hollow shaft design takes up less space.

Reduced mechanical complexity: This type of encoder does not require additional connection components, which reduces installation complexity and costs.

Resistance to environmental conditions: These encoders can perform well in harsh industrial environments with specific conditions.

contact us on WhatsApp at 09890337892426.