Coupling

Coupling is a mean to axle the engine and pump shaft. Coupling In fact, for fusion centrifugal pumps, fusion centrifugal pumps, close pump, in which the shaft and the engine are defective, is connected by coupling.

In fact, the Coupling moves the rotary motion of the motor into the pump shaft and causes the shaft and propeller to rotate. Before connecting couplings, the pump shaft and motor must be coherent.

Typically coupling does not allow the shafts to be separated during operation, although the Coupling can slip or separate when the torque exceeds a higher value.

Coupling is a device for centering the motor and pump shaft. Coupling is actually used for centrifugal motors, centrifugal pumps, close pumps in which the shaft and motor are connected by a coupling.

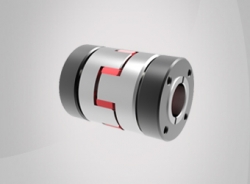

In other words, a coupling is a mechanical device used to connect two shafts (axles) together and transfer power from one shaft to another. This device is used in mechanical systems and industrial machinery and its main purpose is to transfer torque and rotational motion, while minimizing the transfer of mechanical vibrations and shocks.

Features and applications of coupling:

Transfer of torque and power:

- Couplings are used to transfer torque from one rotating shaft to another. This transfer is usually done in pumps, compressors, motors and generators.

Misalignment Compensation:

- In many cases, the two shafts being connected are not exactly coaxial. Couplings can compensate for angular, parallel, or axial misalignments between the two shafts. This feature helps reduce wear and tear on components and increase the life of machinery.

Vibration and Shock Reduction:

- Some couplings are able to reduce vibrations and absorb mechanical shocks that arise from uneven operation or sudden changes in load. This feature can prevent damage to other components of the machinery.

Failure Protection:

- Couplings can act as a safety device, so that in the event of a failure or severe overload, the coupling itself breaks instead of causing serious damage to the machinery.

Types of Couplings:

- Rigid Coupling:

- Examples: Bushing Coupling, Flange Coupling.

- Flexible Coupling:

- Examples:

- Gear Coupling: Has gears that compensate for angular and parallel misalignments.

- Elastomeric Coupling: Uses a rubber or polymer material to absorb shocks and reduce vibrations.

- Diaphragm Coupling: Used to compensate for angular misalignments and absorb shocks.

- Spring Coupling: For applications that require more flexibility.

- Hydraulic Coupling

- Magnetic Coupling

- Encoder Coupling

- Plastic or hydraulic couplings with high torque tolerance made of special plastic suitable for all types of oil tankers in the petrochemical industry

- Gear Coupling

- Claw Coupling

contact us on WhatsApp at 09890337892426.